Key Question:

How can we produce a comfortable and functional lower limb prosthetic socket as a whole by 3D printing?

Work Package Summary

WP3 aims to develop a multi-material print system for materials (especially soft materials) with locally changing properties to be used as socket of a lower limb prosthesis.

The main goals of iMix

- Selection of suitable materials regarding biocompatibility, comfort, lightweight and cost

- Development of hybrid materials and structures regarding the user’s expectations

- Development of multi-material print system and determination of process parameters

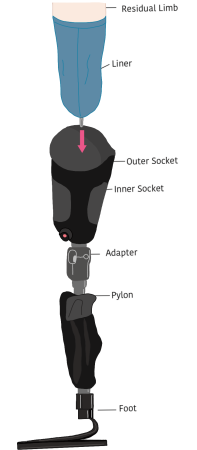

- Development of a prosthetic socket, i.e. outer socket, inner socket and liner as a whole with one-step printing process

Hybrid Materials

Socket and liners, that are the interface between residual limb and the prosthetic device providing the attachment of the prosthesis to the limb, are the most critical parts determining the users’ comfort in lower leg prosthetics. Unlike traditional socket production methods, 3D printing enables us to produce prosthetics faster and customizable production with lower cost.

The main goal of the WP3 is developing a 3D printing method to produce fully customized, functional and comfortable soft sockets and liners with changing mechanical properties at different regions depending on the needs of the user. For inner socket and liner high mechanical load bearing and load transfer capability along with locally changing stiffness and flexibility are desired. To provide these properties together in a one-shot 3D-printing process, in iMix, different material combinations with different structures, their printability, interfacial characteristics, and mechanical and functional properties will be investigated.