Key Question:

How can the toolpath for multi-axis 3D-printing of continuous fibers be optimized?

Work Package Summary

The work package tackles the topics of multi-axis printing and toolpath optimization of continuous fibers. A lot of other challenges are covered in this work, such as controlling of the extrusion rate and printing speed of 5-axis printer and developing a slicing algorithm for multi-axis printing.

The main goals of iPrint

- Solve the kinematic model of the 5-axis printer

- Build a simulation environment of the printing process including the motion of the printer’s parts

- Develop and build a slicing algorithm

- Design an algorithm to solve the toolpath optimization problem for continuous fibers

Printing Strategy

There are two main challenging topics in the field of 3D-printing:

- continuous fibers printing and

- multi-axis printing.

This work package addresses both topics.

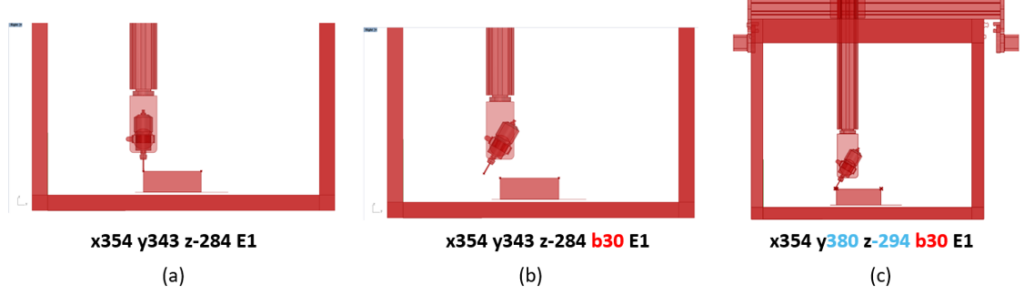

Figure: iLEAD simulation environment for the printer

Multi-axis printing is much harder than normal 3D-printing process due to the complex mechanism of the printer, since it can rotate around the axis and not just move along x-, y- and z-axis. To solve the problem, the kinematic model that describes the movement of the printer’s parts relative to each other has to be calculated. A simulation environment is to be built to visualize the movement of the printer’s parts during the printing process. The conventional slicing software which slices the printed model into vertical layers stacked on top of each other does not work in case of multi-axis printing, therefore, a slicing technique has to be developed.

Continuous fiber printing: When printing with continuous fibers, the fibers have to be aligned with the load direction to achieve the best mechanical properties. For this reason, the printing path has to be optimized. The work package is concerned about designing an algorithm to choose the optimum possible printing path for the different models.