Key Question:

How can we combine developed technologies into a cohesive product?

Work Package Summary

Technology projects often aim to develop a demonstrator at the end, but this can lead to difficulties and interface problems being encountered late in the project. To avoid these traps, WP7 – iProduce coordinates work on iterative Minimum Viable Prototypes (MVPs), which represent the end product using the latest knowledge available, to detect and address future challenges quickly.

The main goals of iProduce

- The main objective of WP7 is to create demonstrators using latest knowledge in cooperation with other WPs.

- Coordination of iterative work over MVPs

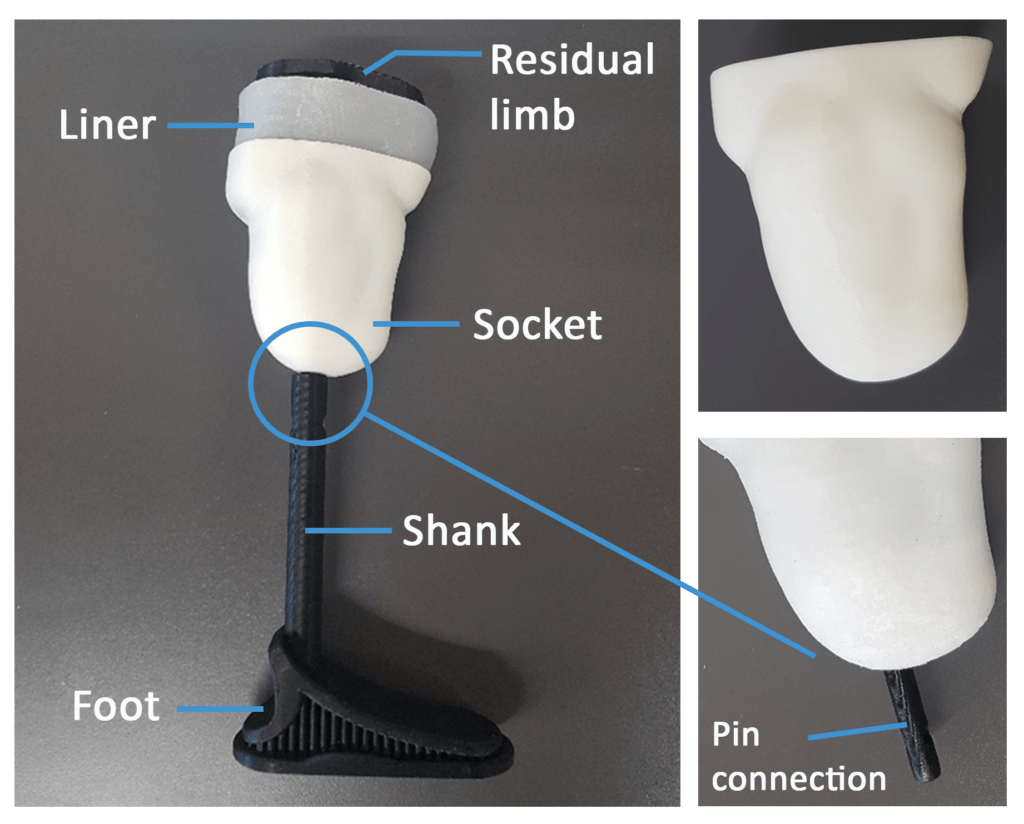

- Development of lower limb prosthesis employing concepts developed in WPs 3-5

- Development of hand assistive device employing concepts developed in WPs 3-6

Final Demonstrators

In order to explore the possibilities of Additive Manufacturing in the creation of medical assistive devices, there are two types of devices being developed: lower limb prostheses and hand assistive devices. This goal will require the collection of specifications in collaboration with orthopedists and therapists, as well as the development of a concept in partnership with technology and medical experts. Additionally, the WP7 aims to identify and address any challenges that may arise in relation to interfaces. By pursuing these steps, the goal is to unlock the potential of Additive Manufacturing in the field of medical assistive devices.

Technology projects often aim to develop a demonstrator at the end of the project. With this approach, difficulties and interface problems have to be faced at a final project stage. In order to avoid this typical project traps, the WP7 – iProduce coordinates the work over the final demonstrators in an iterative approach. This is done by building periodically Minimum Viable Prototypes (MVPs) which represents the final product with usage of current knowledge. Thanks to this approach any future and unexpected challenges can be quickly detected and proper steps can be taken accordingly.