Future Trends in Green Additive Manufacturing

Chair: Lisa-Marie Faller, Fachhochschule Kärnten

Co-Chairs:

Christian Schmid, Fachhochschule Kufstein

Herfried Lammer, Wood KPlus

Martin Kraft, Chasecenter

Topics

AM Technology and Process:

- Printhead and machinery

- Path planning

- Measurement and monitoring

- Process optimization

AM Materials and Design:

- Novel and green materials

- Design strategies for green components

- Design optimization

- Recycling strategies

AM Technology Impact:

- Economical studies

- Life-cycle analysis

- Start-up or network development in AM area

- Opportunities and pitfalls for AM mass production

Summary

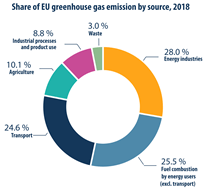

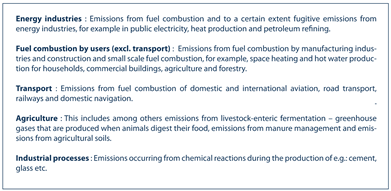

According to Eurostat [1], the major sources of greenhouse gas emission are energy industries, fuel combustion by users followed by transport. Additive Manufacturing (AM) is a part of the technological solution for lowering the greenhouse gas emissions by enabling local production chains, specific demand-triggered production of goods and spare parts and short development cycles support by the related digital design process [2].

Estimates show that the global production volume for AM will grow from around 12 billion US$ at present to 30 billion US$ in the next 4 years [3]. The technology is therefore on the threshold from a niche technology to a mass technology. There are two opportunities behind this development:

(1) AM technology allows the development of innovative products [4]. This is where the advantage of the technology becomes apparent, as it enables a great complexity of shapes and at the same time allows a great variety of materials to be used.

(2) AM technology offers the possibility of producing components and products in a way that saves resources and energy and therefore contributes to green manufacturing [4].

AM therefore offers a great opportunity to close the gap between economic and ecological product manufacturing. However, there are still many questions to be discussed along this path

- Which materials are suitable for green manufacturing, e.g. using cradle to cradle product cycles, and can be produced industrially to a sufficient extent?

- How does an industrial manufacturing cycle using robotics and automation look like to make additive manufacturing economical for larger lot sizes?

- How should products be designed so that they are optimized for additive manufacturing and at the same time are designed to be recyclable?

- What incentive models need to be created to make green manufacturing profitable for the environment and industry at the same time.

- What are the opportunities and pitfalls as additive manufacturing evolves from niche product manufacturing to mass product manufacturing?

Invited are experts in product and material development, developers and implementers of industrial manufacturing processes using AM technology, and experts in technology assessment. Invited are also consumers who use AM products and, in general, anyone who is passionate about sustainable production through green AM.

References

[1] https://ec.europa.eu/eurostat/cache/infographs/energy/bloc-4a.html (accessed 01.11.21)

[2] M. Despeisse et al., Unlocking value for a circular economy through 3D printing: A research agenda, Technological Forecasting and Social Change, Volume 115, February 2017, Pages 75-84

[3] https://www.statista.com/statistics/315386/global-market-for-3d-printers/ (accessed 01.11.21)

[4] https://www.oecd-ilibrary.org/science-and-technology/the-next-production-revolution/3d-printing-and-its-environmental-implications_9789264271036-9-en (accessed 01.11.21)

Alle Panels unterliegen den Einreichkriterien von Track 3.

Hier geht’s zu den Einreichkriterien Call For Papers – Track 3